FPS 300M

Axial ranges of motion

X: 300 mm

Y: 160 mm

Z: 340 mm

(The cutting head can also be moved an additional 100 mm along the Y-axis)

Mehr Ergebnisse...

FPS 300M

FPS 500Mhydro

FPS 300M

FPS 500Mhydro

FPS 300M

FPS 500Mhydro

Axial ranges of motion

X: 300 mm

Y: 160 mm

Z: 340 mm

(The cutting head can also be moved an additional 100 mm along the Y-axis)

Axial ranges of motion

X: 500 mm

Y: 350 mm

Z: 400 mm

(The cutting head can also be moved an additional 150 mm along the Y-axis)

| FPS 300 M | FPS 500 Mhydro * | |

Operating area |

||

| X-axis | 300 mm | 500 mm |

| Y-axis | 160 mm | 400 mm |

| Z-axis | 340 mm | 400 mm |

| Cutting head can also be moved further along the Y-axis | 100 mm | 150 mm |

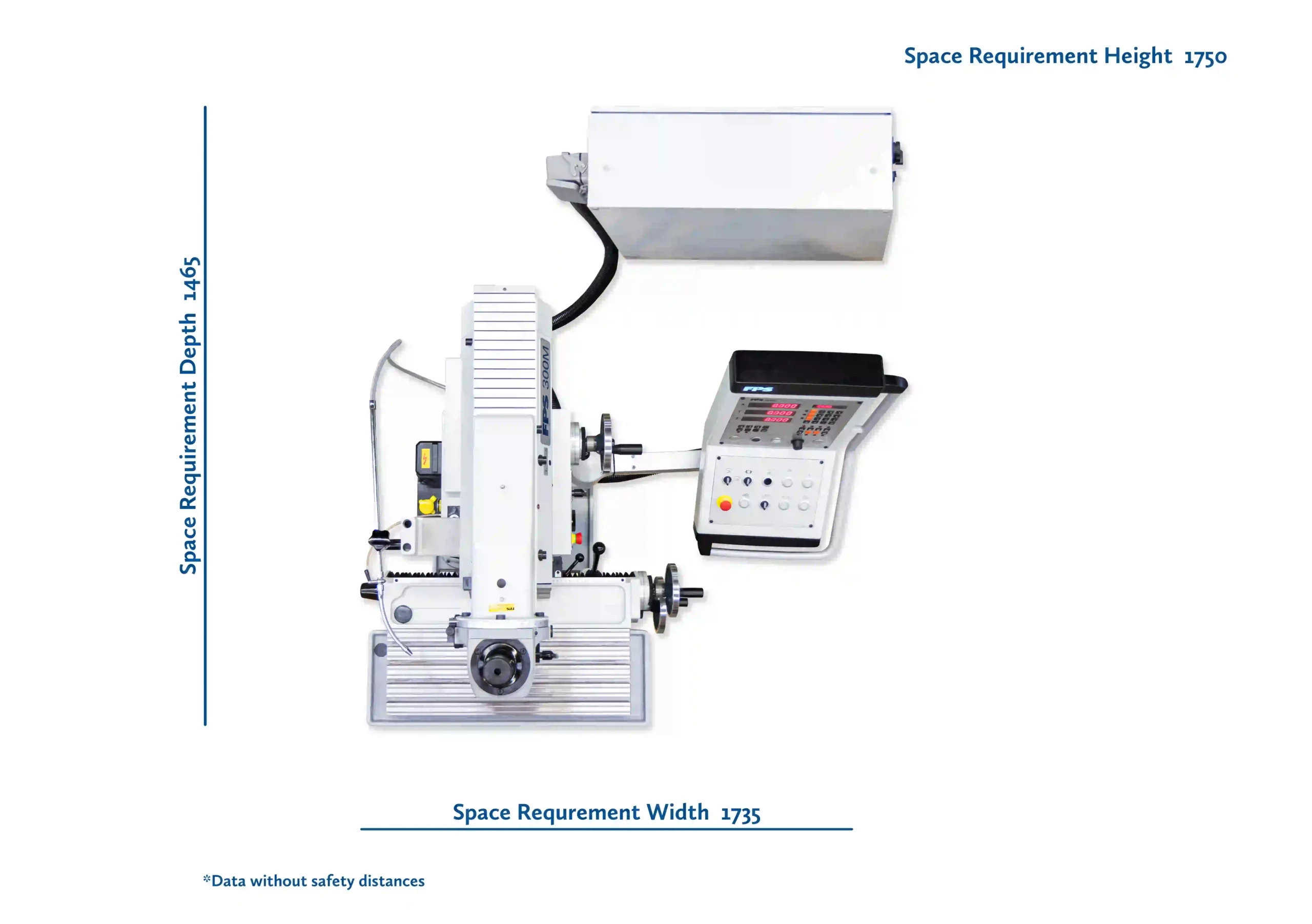

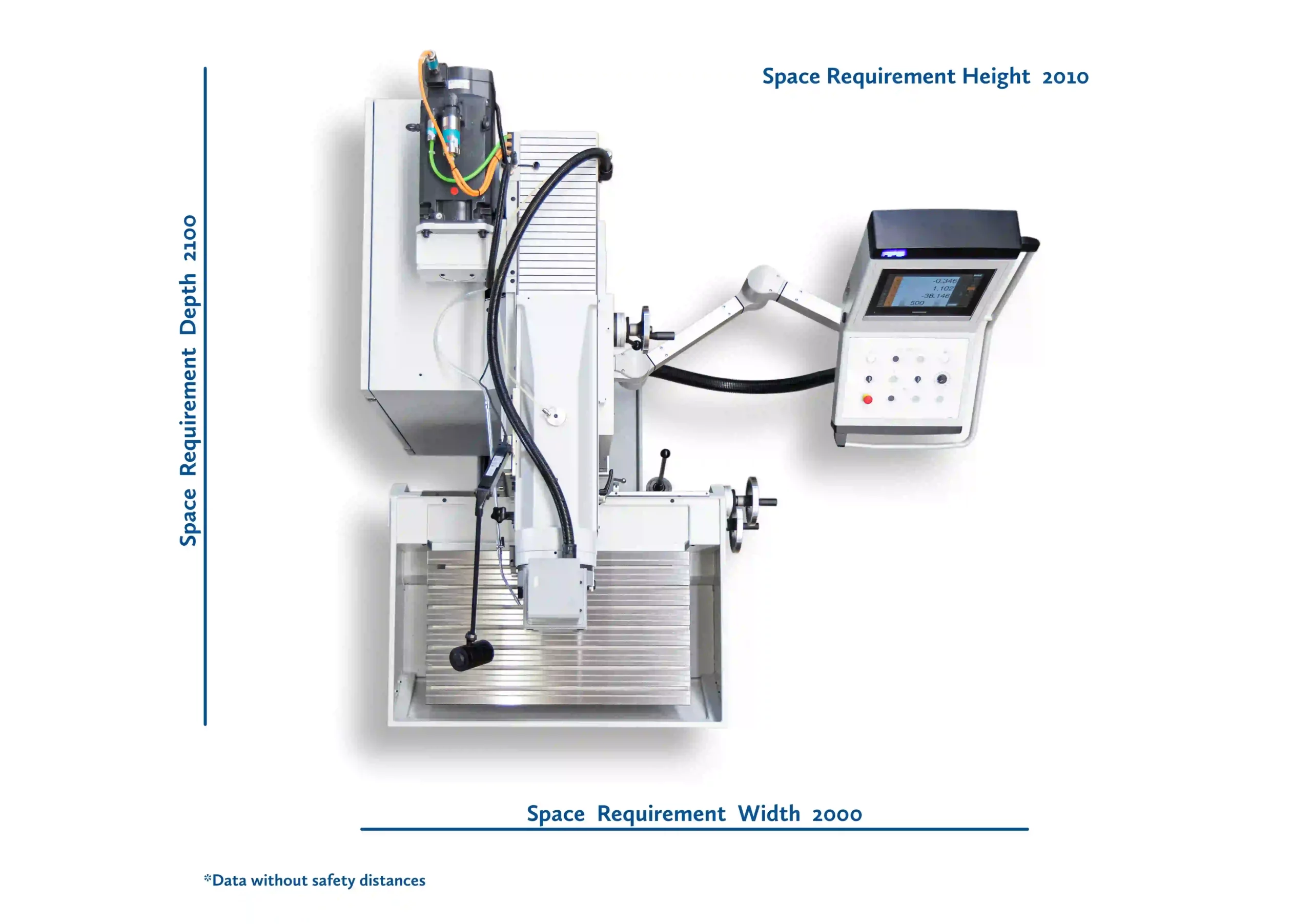

| W x D x H space requirement | 1735 x 1465 x 1725 mm | 2000 x 2100 x 2010 mm |

Solid angle table |

||

| Table/clamping surface | 210 x 600 mm | 800 x 480 mm |

| T-grooves: Number / width / distance | 5 / 12 H7 / 45 mm | / 14H12 - Richtnut 14H7 / 63 mm |

| Permitted load | 200 kg | 300 kg |

Operating spindle |

||

| Vertical and horizontal | hoizontal (optional) | |

| Vertically extending as drill spindle, with clamp/stroke | approx. 60 mm | - |

| Horizontally extending as drill spindle, with clamp/stroke | approx. 60 mm | approx. 100 mm (optional) |

| Manually rotating cutting head | +/- 90° | +/- 90° |

Tool holder |

||

| Manual ISO 40-DIN69871 tightening system | M16 | - |

| or optional variant in line with DECKEL standard | S 20x2 | - |

| Hydraulic tightening system | - | DIN 69872* |

| or optional variant* | - | DIN 2080* |

Main drive, three-phase-current brake motor |

||

| Power | 1.4 / 1.8 KW | 7.0 kW |

| Gear stages (clockwise/anti-clockwise) | 8 | Direct drive |

| Speed range | (16 stages) 40 to 2000 rpm | 25 to 3000 rpm - stepless adjustable |

Feed drive, digital drive |

||

| Feed rate, stepless adjustable | 5 to 500 mm/min | 5 to 500 mm/min |

| Rapid feed | 1200 mm/min | 1500 mm/min |

| Control wheel manual rotation | X-axis, 4.0 mm Y/Z-axis, 2.5 mm | X/Y/Z-axis, 2.5 mm |

Connection |

||

| Mains connection | 3 x 400 V AC, 50/60 Hz | 3 x 400 V AC, 50/60 Hz |

| Power consumption | 6 kVA | 7 kVA |

| Max. backup fuse | 20 A | 35 A NH |

Control cabinet electronics |

||

| CE-compliant in line with current regulations of professional associations | BGVA 3 / DIN EN 60204-1 | BGVA 3 / DIN EN 60204-1 |

Weight |

||

| Total machine weight incl. machining table and cutting head | approx. 770 kg | approx. 1600 kg |

| Control cabinet | approx. 140 kg | - |

Our 3-axis digital display ensures absolute operation convenience. It enables the user to precisely position the incremental dimension (incremental) and the distance dimension (absolute). This is basis for quick and successful training and simple solutions for manufacturing – even for more complex tasks.

The new Heidenhein Positip 8016 offers even more operating comfort through touch operation. In addition to precise positioning of the incremental and distance dimension. You benefit from extended functions such as bore hole circle calculator and tool memory. Recurring work processes can be grouped together in programs.

Our conventional machines are suited for different machining tasks, because they offer you the same versatility you are used to from manual DECKEL machines.

Both in operation and maintenance, our machines impress with a highly flexible overall concept.

Extra Y-axis space

The vertical milling head can be moved by an additional 100 or 150 mm in the longitudinal axis. This increases your X/Y-axis working area to 300 x 260 mm or 500 x 500 mm.

Angular machining

Swivel the vertical milling head in any position to the right or left by each +/- 90°.

The number of degrees is adjustable by a scale.

By a lock the milling head is brought easily into vertical position again.

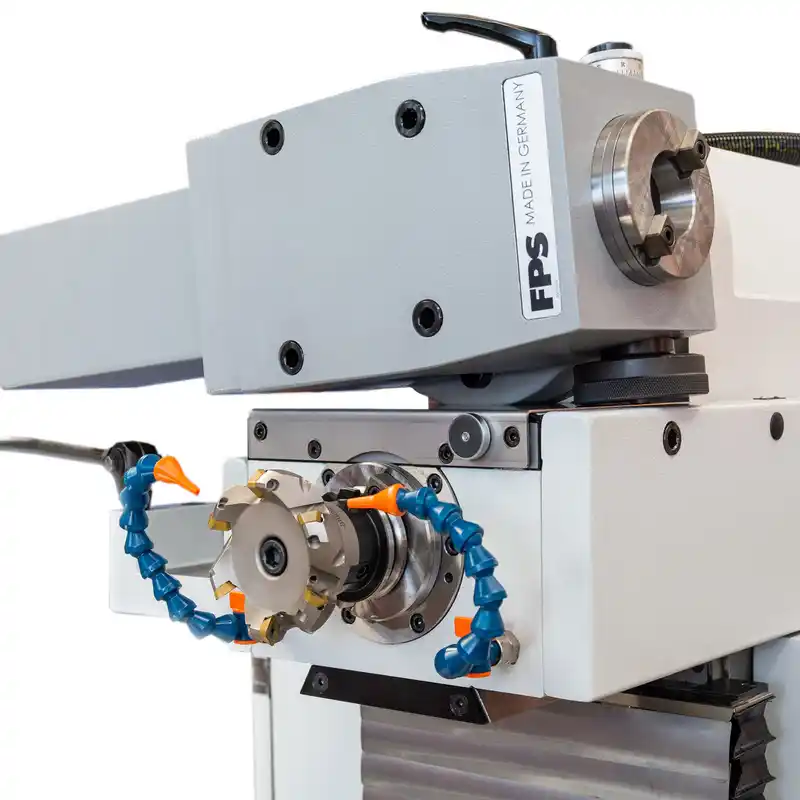

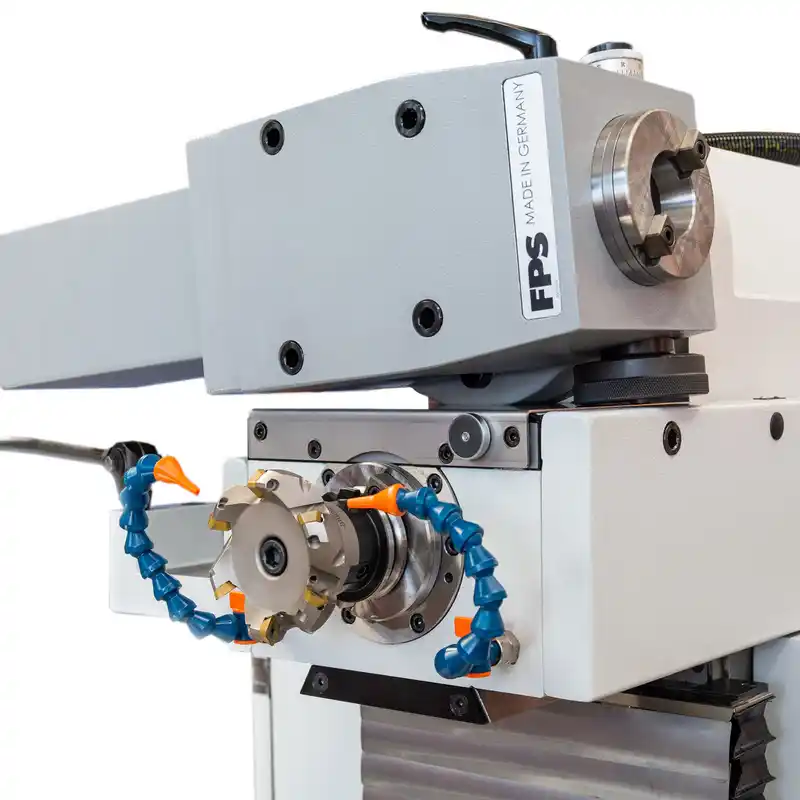

Milling and drilling

The vertical spindle is extendable by 60 respectively 80 mm and can be used as drilling pinole as well.

Safety hand wheels

Manual, mechanical hand wheels in all axes.

Vertical or horizontal

The milling head can be swivelled by 180°, allowing you to convert the working area from vertical to horizontal and back again.

Extra Y-axis space

The vertical milling head can be moved by an additional 100 or 150 mm in the longitudinal axis. This increases your X/Y-axis working area to 300 x 260 mm or 500 x 500 mm.

Angular machining

Swivel the vertical milling head in any position to the right or left by each +/- 90°.

The number of degrees is adjustable by a scale.

By a lock the milling head is brought easily into vertical position again.

Milling and drilling

The vertical spindle is extendable by 60 respectively 80 mm and can be used as drilling pinole as well.

Safety hand wheels

Manual, mechanical hand wheels in all axes.

Vertical or horizontal

The milling head can be swivelled by 180°, allowing you to convert the working area from vertical to horizontal and back again.

Extra Y-axis space

The vertical milling head can be moved by an additional 100 or 150 mm in the longitudinal axis. This increases your X/Y-axis working area to 300 x 260 mm or 500 x 500 mm.

The main assemblies of our machines are positioned in a way that ensures easy maintenance. All important

machine modules can be accessed directly from the rear of the machine. Another incredibly useful feature of the machine is its automatic central lubrication system for all axes and the vertical milling head.

Despite our machines’ compact installed dimensions, they pack a surprising punch while being incredibly accessible. This makes our FPS 300M, FPS 500M and FPS 500Mhydro machines also suitable for workshops with limited installation space.

FPS 300M

FPS 500M-hydro

FPS 500M-digital | FPS 630M-digital

FPS 425M-NC | FPS 630M-NC

FPS 420 M-NC | FPS 620 M-NC

Mehr Ergebnisse...